Introduction

Sample preparation is of paramount importance. Following are the options/best practices for preparing solid, liquid and gas samples for the XAS endstation. Our sample holders are highly customizable and can be adapted for mounting almost any type of sample. We have a anaerobic chamber to ensure that samples are exposed to minimum amounts of air, which is discussed below.

Consult with beamline staff for an alternative mounting strategy.

The beam spot size is routinely 50 um x 50 um. Consult with beamline staff to change the beam spot size.

Solid Sample Preparation

The typical methods for mounting powder and coupon samples on the XAS endstation include:

Powders:

(a) powders are pressed into pellets, without binders such as BN, into 3 x 3 mm rings (maximum 6 samples per holder). The standard ring used is that of Al but stainless steel and Zn rings are available upon request. About 0.1 g of sample is required to form a pellet. Samples must be finely ground to facilitate pellet formation. SGM beamline staff cannot be expected to grind samples. Occasionally some samples cannot be pressed into a pellet for a number of reasons such as to little sample, particle size to large, static, to dry, etc. In these cases, alternative methods need to be explored.

(b) powders are pressed onto double-sided tape (e.g., C, Cu, Al) using the flat part of a spatula on either an aluminum, steel or brass plate, which are then mounted onto the standard teflon sample holders.. If surface coverage is poor, the spectrum from the tape may contribute to the overall spectrum. Hence, a spectrum should always be collected from the tape itself (i.e., without any sample), for the appropriate edges, to determine that the tape spectrum has not contributed significantly to the sample spectrum. To avoid contamination of samples from other samples, it is highly recommended that samples be pressed first onto the tape on a separate plate/glass slide, subsequently the tape with the pressed powder is moved to the plate containing all the samples for measurement.;

(c) powders are pressed into indium foil, which is highly pliable. This method requires that a very small piece of indium be cut, flattened using a spatula and then the sample is pressed into the indium using a spatula. The indium can then be fastened to an Al, stainless steel or brass plate. As for the tape, prepare the sample on a separate plate to avoid sample contamination, and collect a spectrum of a flatted indium foil enure that the indium did not significantly contribute to the sample spectrum;

(d) powders can be dispersed in a suitable solvent (e,g, water, methanol) and drop-deposited onto a suitable substrate ( e.g., Au coated Si wafers (5 x 5 mm)) and then dried in air, under vacuum or in an inert atmosphere. ;

Coupons: These are oddly shaped/stand-alone samples (e.g., meteorite, rebar, tooth, carbon paper) or samples affixed to a substrate by the User (e.g., battery component, soil core). The materials will be fastened to either Al, stainless steel or brass plates using double sided carbon tape. The maximum area accessible to the beam, is about 16 mm x 8 mm. The size should not exceed 5 x 5 mm to facilitate putting more than one sample on the sample holder or be more than 3 mm thick due to space restrictions imposed by the SDD. SGM beamline staff can not be expected to cut coupons.

IMPORTANT. Sometimes it is not easy for the beamline staff to tell which side the sample is on when the sample (e.g., carbon sample on carbon paper) is just loose in a vial/bottle. For these kinds of samples , where cross contamination is not an issue, we recommend that you mount the samples onto the SGM sample plates in your laboratory and send them that way. Or alternatively, instead of having them loose in a vial, attach them with double sided C-tape in a petri dish, each sample in its own petri dish if cross contamination is an issue. This way we know which side the sample is on. You can contact us for the ordering information for the sample plates (Al, Steel, Brass) we use on the beamline. We order from McMaster Carr (about $12 to $25/100 plates), depending on the type ordered) and they are usually delivered within 2 or 3 days after they receive the order.

Suspensions: These can be pipetted onto Au coated Si wafers or other substrates and air-dried or by another method such as heating..

Air-Sensitive Samples: Samples that are air-sensitive can be mounted in an anaerobic chamber in a glove box. For more details see the anaerobic chamber section below.

Consult with beamline staff for other mounting options.

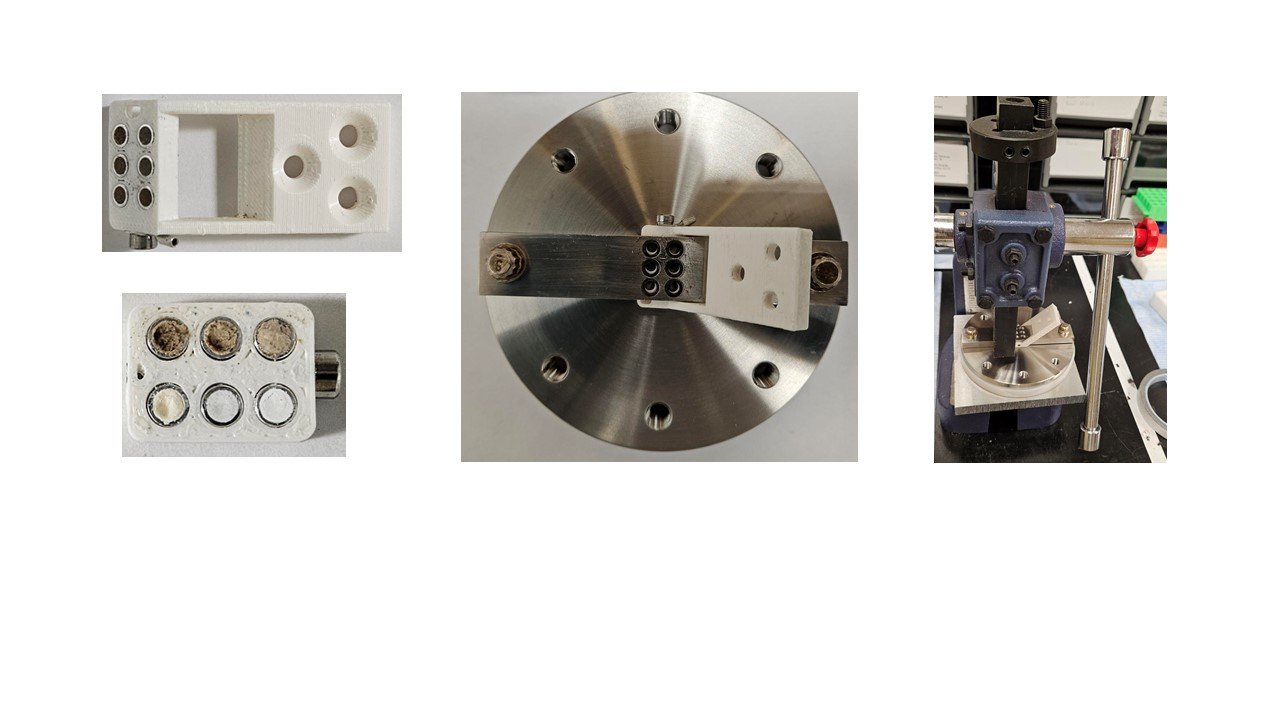

Figure 1. Pressed powder samples. Holders (left), sample holder on stainless steel platform ready for fill (middle) and press with sample holder on platform.

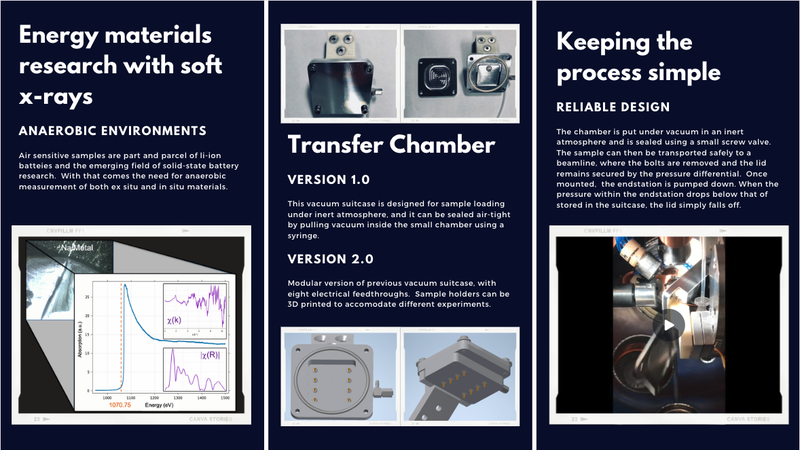

Anaerobic Chamber

Many of the most important energy materials are highly sensitive to oxygen and water in the atmosphere and have to be handled in an anaerobic environment to maintain their useful properties. This presents a challenge for analyzing these materials using x-ray spectroscopies because the controlled environmental conditions must be maintained throughout the production, preparation, transfer and analysis stages of the experiment. This is particularly important for soft x-ray spectroscopies where probe depths are very shallow and even a brief exposure to atmospheric conditions can degrade the sample surface and affect the measurements.

The development of the SGM beamline anaerobic sample holder addresses the needs of the energy material research community by providing an end-to-end anaerobic sample transfer capability. The system consists of a sealable sample holder that can be loaded and prepared in a glove box. Once the samples are mounted, the system is sealed and the contents are put under vacuum using a syringe.. The holder can then be safely taken from the glove box and loaded into the measurement endstation. When the endstation vacuum reaches the vacuum level inside the holder, the lid falls away, exposing the sample for measurement.

The holder is currently available for general use. Currently not available for sample mail-in program. Recent updates include the addition of electrical feedthroughs for in-situ and operando measurements. Please contact SGM beamline staff to discuss use of the anaerobic sample holder.

An anaerobic chamber that houses our Al, stainless steel or brass plates is available to mount air-sensitive samples (powders, coupons) in a glove box under either an Ar or N2 atmosphere. The removable lid on the chamber is sealed/fastened to the chamber body by pulling a partial vacuum using a syringe. Inside the XAS chamber the lid falls off of the anaerobic chamber when the pressure of the XAS chamber (~10-6 Torr) is less than that of the anaerobic chamber. An anaerobic chamber with electrochemical capabilities is available. Consult with beamline staff for particulars.

Liquid Cell

An in-house liquid cell is available for continuous flow through, and static electrochemical experiments. Standard cell uses a 100 nm thick, 1 mm2, Si3N4 window to separate the liquid from the vacuum chamber. Can also accommodate user designed liquid cells, in collaboration with beamline staff. Please contact well in advance of experiment.